The company has been passed down from generation to generation and remains a family business. Established in 1909, in Milan, Italy by engineer Luigi Boldrocchi. We have over 115 years of experience.

My grandfather started Boldrocchi in 1909 as a fan company. Over a hundred years later, Boldrocchi Group has become a world-renowned engineering, manufacturing and service firm with products in over 140 countries and offices in eight, including our headquarters near Milan, Italy. It is among the few companies in the world that offer a wide-ranging portfolio of solutions that includes fans, blowers & compressors, air pollution control & environmental solutions, heat exchangers & coolers, gas turbine systems & noise protection and heavy-duty process dampers, among other equipment.

At Boldrocchi, we pride ourselves on being forward-thinking experts and tailor-making each solution for every client. We put quality first. Quality when it comes to our technical advice, engineering solutions, manufacturing, testing, installation, commissioning and service. We want the Boldrocchi name – my family name – to remain synonymous with the highest quality products, solutions and service.

– Massimo Boldrocchi

About Us

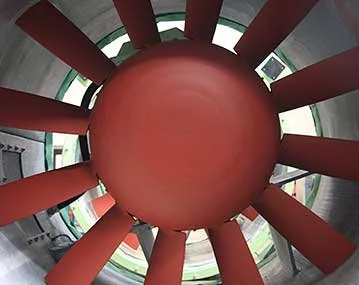

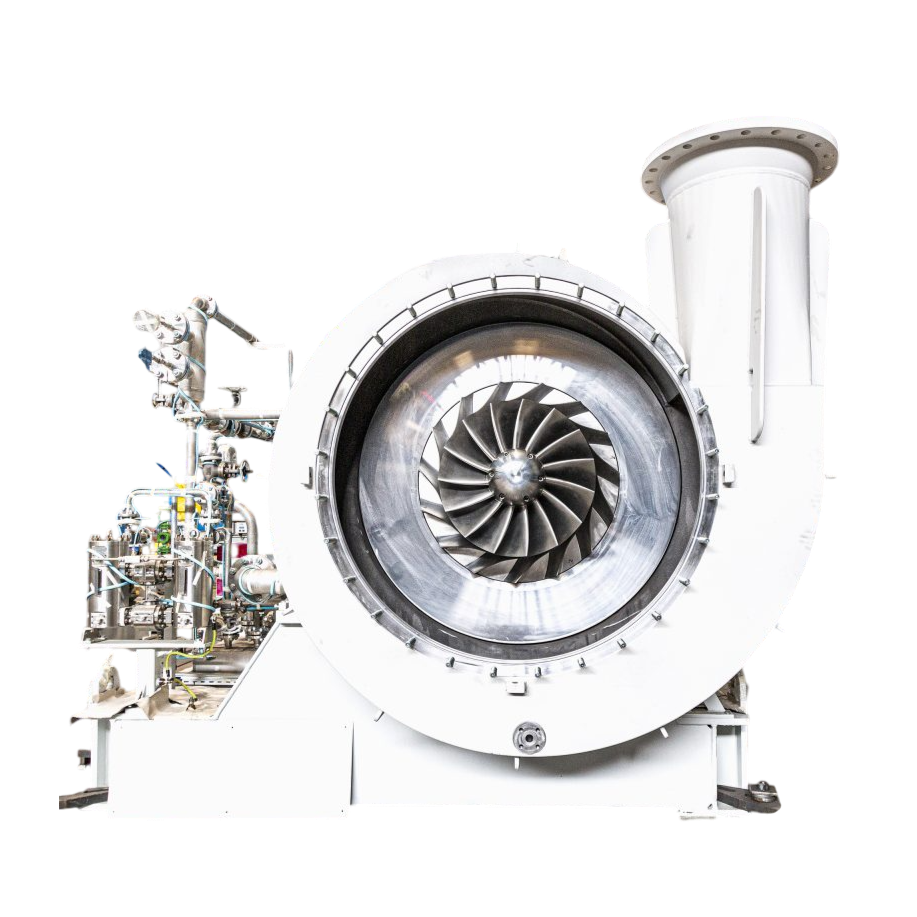

Fans, Blowers & Compressors

Boldrocchi is one of the oldest and most experienced rotating equipment manufacturers in the world, as our first industrial fan installation dates back in 1909. With more than a century expertise we can cover virtually any industrial application with the highest quality standards and leading-edge technology in the market.

Our solutions, easy to maintain, durable and efficient have been positively installed and operated by major end users in various heavy industry sectors all over the world. All our fans, blowers and compressors can be tested in our 3.000m2 state of the art testing facility where almost any test can be performed and even be witnessed by clients from remote.

Boldrocchi rotating equipment product range include:

-

Flow rates up to 2,500,000 m3/hr (1,470,000 ft3/min)

Installed power up to 10 MW (13,000 hp)

Tip speeds over 220 m/sec (720 fps)

Special blades design, such as air foil profile, to ensure extreme efficiency and low power absorption, as well as specialty fans such as for chlorine processing and steam compression

High yield materials including S690QL, ASTM 514

Corrosion resistant materials including stainless steels, duplex steel, titanium, Inconel, Hastelloy, etc.

Special liners & coatings, including hard rubber liners and glass flake coating

Wear resistant materials including Creusabro®, Vautid®, chromium carbide & tungsten carbide plates

Design according to API 560, API 673

ISO 9001

-

Integrally geared solutions

External gear systems for gas applications or large size units

Flow rates: 1,500 to 300,000 m3/h (883 to 17.650 ft3/min)

Pressure ratio: 1.5 to 19 (Multistage)

Reliable continuous operation with minimum maintenance

Higher efficiency: up to 85%

Oil-free application

Products

-

Flow rates up to 500,000 m3/hr (294,290 ft3/min)

Installed power up to 5 MW (6,500 hp)

Tip speeds over 280 m/sec (920 fps)

Hot-gas circulating fans up to 650°C (1200°F) – max. 850°C (1560°F)

Special blades design

Single, double or multi-stage blowers: ≤ 4 MW (5,360 hp) of installed power, pressure rise ≤ 900 mbar (13 psi)

Special blowers have been made with heads up to 65 KPa and ≥ 1,000 KW power

Suitable for any gas, even:

Corrosive and lethal service

High temperature

ISO 9001

-

Speed ranges: typically, 1500 ÷ 5000 rpm

System pressure: 0.2 ÷ 100 bar (a)

Pressure ratio: within 1.2 ÷ 1.8 in standard applications

ΔT = 5÷10 K for each stage of compression

Flow Rate: within 5.000 ÷ 500.000 [m3/h]

Capacity: within 100.000 kg/h under vacuum, 500.000 kg/h in ambient pressure condition

Oil free, non-pulsating operation.

Turn down ratio > 25%

Heat Exchangers & Coolers

Boldrocchi has been manufacturing coolers since 1931. We tailor-make each one to our customers’ specifications. We are also specialists at analyzing your process parameters to find you the optimal process or machine cooling solution

Boldrocchi product range include:

Electrical Machine Cooling

Tip speeds over 280 m/sec (920 fps)

Hot-gas circulating fans up to 650°C (1200°F) – max. 850°C (1560°F)

Special blades design

Single, double or multi-stage blowers: ≤ 4 MW (5,360 hp) of installed power, pressure rise ≤ 900 mbar (13 psi)

Special blowers have been made with heads up to 65 KPa and ≥ 1,000 KW power

Suitable for any gas, even:

Corrosive and lethal service

High temperature

ISO 9001

Appropiate for

Gaseous & liquid hydrocarbons, steam, vapors

Water & lube oil closed circuit systems

High pressure intercoolers & after coolers

Compressed air & gas coolers

Gas heaters & coolers

Air pre-heaters & heat recuperators

Special applications

Air Cooled Heat Exchangers

High pressure & temperature options

Customization to withstand the most demanding circumstances and locations:

Extreme temperatures

Corrosive environments

Seismic areas

Other demanding conditions

Expert problem-solvers for complex installations

Mechanical design meeting ASME, API 661, “U” & “CE” stamps available, CUTR adherence available

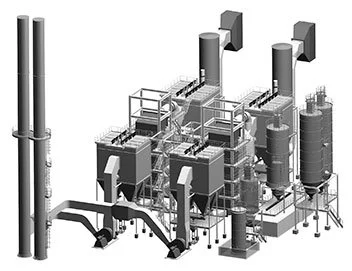

Air Pollution Control & Environmental Solutions

Our dust removal solutions can achieve practically zero emissions: 0.1 mg/Nm3 (0.06 gr/ft3) (WTE applications). Our flue gas treatment solutions remove: dust, acid gases, nitrogen oxides, sulfur oxides, mercury, furans, hydrochloric acid, dioxins and other heavy metals. We offer everything needed to meet or surpass all air emission regulations worldwide

What we offer:

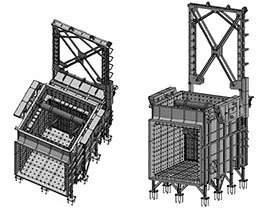

Heavy-Duty Process Dampers

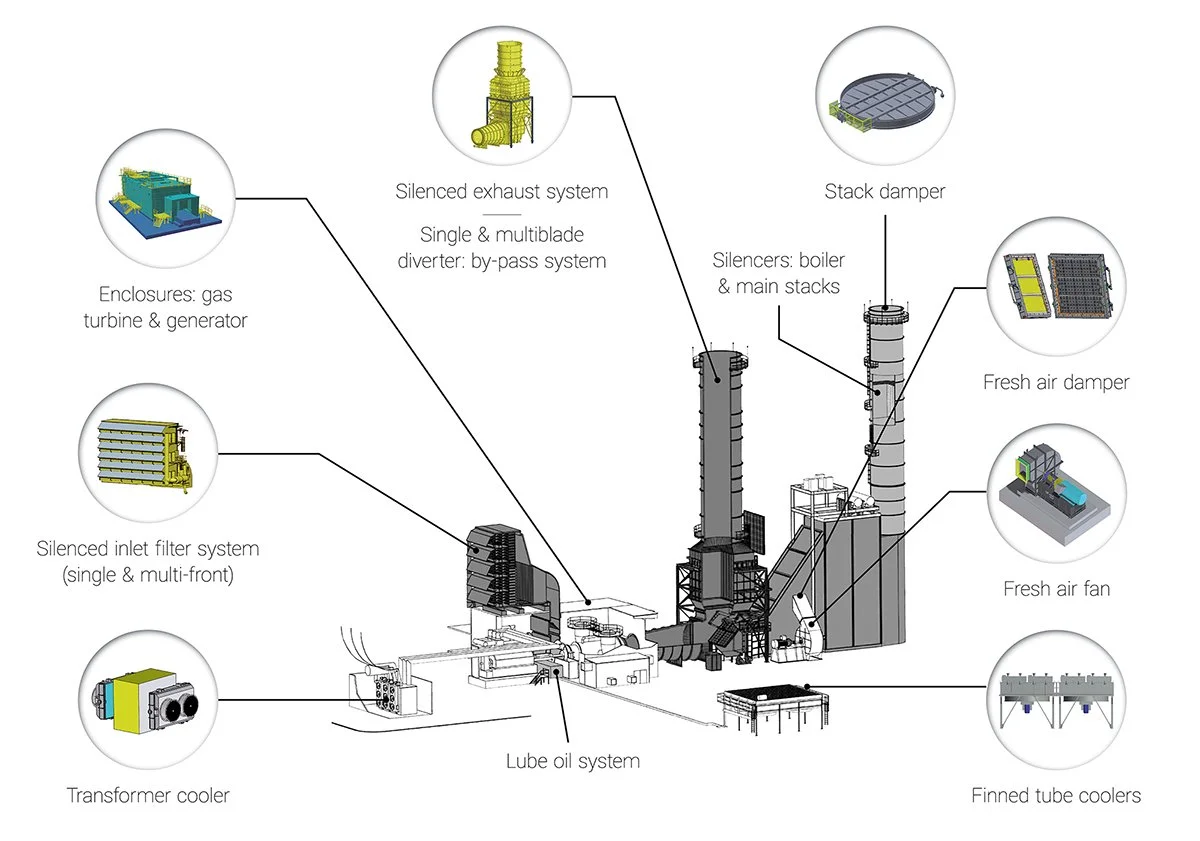

Boldrocchi has been engineering and manufacturing auxiliaries and noise protection solutions for gas turbine, turbo machinery and compressor, for over 55 years. Our equipment and expertise can be found in thousands of power generation, oil and gas, offshore and gas transmission operations around the globe. We have a considerable track record in greenfield installations and thanks to our long presence in the market, we have significant experience offering you high quality upgrade and retrofit solutions as well.

Gas Turbine Systems & Noise Protection

Boldrocchi has been engineering and manufacturing auxiliaries and noise protection solutions for gas turbine, turbo machinery and compressor, for over 55 years. Our equipment and expertise can be found in thousands of power generation, oil and gas, offshore and gas transmission operations around the globe. We have a considerable track record in greenfield installations and thanks to our long presence in the market, we have significant experience offering you high quality upgrade and retrofit solutions as well.

Key Gas Turbine & Noise Protection Projects

Our Integrated Approach for Gas Turbine Power Plants

AIR INTAKE SYSTEM

We supply fully equipped air inlet filtration system for Gas turbine and different turbomachinery (generators, centrifugal compressors and diesel engines) including inlet duct system, silencer, filter housing, anti-icing, preheating and inlet air cooling.

EXHAUST GAS SYSTEM

We offer complete exhaust gas systems for gas turbines (both for open cycle and combined cycle) including diffuser, bypass diverter dampers (single & multi-blade), guillotine dampers, hot silencers, vertical stacks.

NOISE PROTECTION

Our industrial noise experts can boost unique experience (more than 50 years) in industrial noise equipment and solution to match the strictest noise requirements.

SCR CATALYST & CATALYST OXIDATION SYSTEM

Gas turbine CFD designed complete SCR Catalyst Systems (NOx) and Catalyst Oxidation Systems for Carbon Monoxide (CO) or Volatile Organic Compounds (VOC) reduction solutions including dosing, recirculation and dilution systems. One single technology supplier and single source responsibility for environmental compliance downstream the gas turbine.

Services

Complete on-site & data-based needs analysis

Initial performance tests (according to ISO and AMCA standards)

Situation analysis and reports

Advisory services

Recommendations to meet objectives/legislation

Plan elaboration

Installation and erection

Installation and erection supervision

Commissioning

On-site & classroom training

Maintenance services

Inspections guidance & preparation

Spare parts